Wireless Remote Control Grab

Description:

Wireless remote control grab, widely known as a new type of single rope grab, is typically used for handling bulk material cargoes. Our grabs are equipped with a hydraulic system to control the closing of the grab. By pressing the remote control a signal is sent to the grab. The receiver that is inside the grab activates an electro-magnetic valve inside the hydraulic system, which starts the opening of the scales. The key components of electrical and hydraulic systems are of recognized brand imported. The water-proof design of the grab allows for all weather operations. Wireless remote control grabs are specifically used for loading and unloading application in ports and terminals.Available from 2.2 M3 to 10 M3 and for lifting capacities from 7.5 to 32 ton

There are dedicated grabs for various common bulk materials.

Application:

Used for handling various kinds of materials including grain, coal, ore, metal, plastics, cement, clinker, gravel, etc. The grabs can be fitted on all type of cranes: mobile, crawler, port, ship, etc.Features:

1. Wire distance can be 100m. DC power supply: 24V. The grab comes with a storage battery cell, so it allows for constant use for 80 hours.2. Cost-saving: the cost of a wireless remote control grab is about haft of an electro-hydraulic grab. And it functions as well as an electro-hydraulic grab. It is a popular material handling equipment worldwide, which is seen as a perfect supplement to any general cargo crane.

3. The opening mechanism is hydraulically controlled by remote control. And by means of that, additional staff is not needed to open the grab.

4. The degree of load release is able to be controlled incrementally for a precision hour.

5. Fast operation and environmental friendly: The deployment of hydraulics in the design saves cycle time and wear and tear on the crane.

Advantage:

1. Our company has been engaged in developing wireless remote control grabs since the year 1993. We were awarded Gold Medal in an American display of remote control bulk grab in 1994. The new generation of our remote control grab adopts virtual design, and the main components will be tested by means of ANSYS analyses.2. The grab components are modular designed for the ease if maintenance.

3. Water-proof and wear resistant design: every set of our grab has gone through a 24 hours immersing test.

4. The opening of the grab is controlled by a multi-level buffering for the protection of the equipment.

5. Our grabs can work at least 24 hours before recharging is necessary.

6. Easy operation: It is easy to operate without any special accessories.

7. No need for a cable drum system, electric cable, electric panel in the crane, and pedals.

8. Long life span.

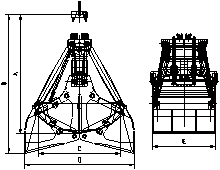

Product Outline:

Technical Parameter:

| Lifting Capacity SWL (t) | 7.5 | 10 | 15 | 20 | 25 | 32 | |

| Capacity Volume (400 Dome) (m3) | 2.2 | 3 | 5 | 6 | 8 | 10 | |

| Sheaves Diameter Æ(mm) | 445 | 500 | 560 | 650 | 720 | 800 | |

| Cable Specification Æ(mm) | 21.5 | 24 | 28 | 32 | 36.5 | 40 | |

|

Parameter (mm) |

A | 2700 | 3000 | 3300 | 3600 | 4000 | 4400 |

| B | 3200 | 3500 | 4000 | 4300 | 4700 | 5000 | |

| C | 2200 | 2400 | 2700 | 2940 | 3300 | 3600 | |

| D | 2900 | 2800 | 3400 | 3560 | 4200 | 4400 | |

| E | 1600 | 1840 | 2000 | 2100 | 2200 | 2600 | |

| Dead Weight (t) | 3 | 4 | 6 | 7 | 9.2 | 11.5 | |

| Operating Height (m) | 9 | 10 | 11 | 12 | 13 | 15 | |

| Remark |

|

|

|

|

|

|

|

Typical Cases 1:

(2). New Zealand International Terminal Limited Company

(3). Shanghai Leading Energy Shipping Limited

(4). hanghai Zhenhua Heavy Industries Co., Ltd.

Typical Cases 2:

(2). Shanghai Port Dongchang Harbor Company

(3). Zhuhai International Terminal Limited Company

Related Products

-

- Motor Hydraulic Dual Scoop GrabElectro hydraulic grab with dual scoop can be fitted to the crane with one single rope. It is an efficient tool for load

-

- Motor-Hydraulic Rectangle GrabMotor-hydraulic rectangle grab is mainly with single hook crane for waterway cleaning up garbage or for steel scrap and