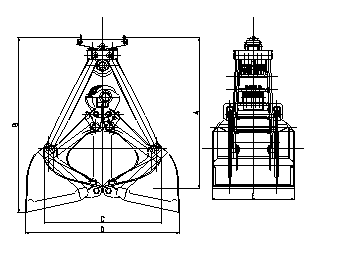

Four-Rope Mechanical Dual Scoop Grab

Description

Four-rope mechanical grab: 2 holding ropes and 2 closing ropes. The grab buckets are designed with robust structure, with strong grabbling ability and 95~100% fullness degree. They achieve maximum efficiency through the optimum balance between dead weight and crane capacity. Scoop designs are with various sealing systems, which can be supplied on client’s request.Four ropes dual scoop grab is normally fitted on various cranes, port, deck, ship unloaders and other type of cranes, widely used in steel plants, power stations and vessels. Our company holds leading technology in developing a comprehensive range of grabs, with lifting capacity ranging from 5 to100t.

Application:

This four-rope mechanical grab with dual scoop is the best tool and efficient tool to grab particle loose bulk cargo, loading and unloading granular, powder, small-block bulk cargo, such as coal, coke, ore sand, steel scraps and other bulk material.Product features

1. High strength and light self weight2. The overall structure of clamshell grab bucket is light and durable, offering high grabbing ratio, strong closing force and high material filling rate.

3. Main shaft sleeve is of bearing steel, Pin shaft material is 40Cr

4. High temperature resistant bearing for pulley

5. Knife edge plate adopts wear-resisting steel plate

6. Low maintenance

7. Our well-equipped facilities and excellent quality control throughout all stages in the production of mechanical grab enable us to guarantee total customer satisfaction

Six types of four-rope clamshell grab bucket:

Quality Advantage (with more technical information on material requirements, processing technology, and structure requirements):

Products Outline:

Technical Parameter:

| Specification | Volume (m3) | Material Density (t/m3) | Dead Weight (t) | Outline Dimension (mm) | Chain Wheel Diameter (mm) | Operating Height (m) | Steel Rope Diameter (mm) | Lifting Height (t) | ||||

| A | B | C | D | E | ||||||||

| CS3[1.0]1.4A | 0.6(300) | 2.5 | 1.5(5) | 1400 | 1927 | 1849 | 2105 | 1000 | Ø350 | 7 | Ø12 | 3 |

| CS3[1.0]1.4A | 1.0(350) | 1.2 | 1.4(4) | 1600 | 1990 | 2265 | 2617 | 1100 | Ø350 | 7.5 | Ø12 | 3 |

| CS3[1.5]1.4A | 1.5(400) | 1.2 | 1.4(4) | 1800 | 2570 | 2406 | 2892 | 1300 | Ø350 | 8 | Ø12 | 3 |

| CS5[0.5]2.0A | 0.5(200) | 3.5 | 2(5) | 1600 | 2144 | 2496 | 2809 | 1100 | Ø400 | 9.0 | Ø15.5 | 5 |

| CS5[0.75]2.0A | 0.75(200) | 3.5 | 2(5) | 1800 | 2477 | 2713 | 3147 | 1100 | Ø400 | 9.5 | Ø15.5 | 5 |

| CS5[1.1]1.4A | 1.1(300) | 3 | 1.4(4) | 1800 | 2338 | 2596 | 2957 | 1050 | Ø400 | 8.5 | Ø15.5 | 5 |

| CS5[1.5]2.0A | 1.5(300) | 2.0 | 2.0(4) | 1800 | 2482 | 2659 | 3138 | 1400 | Ø400 | 8.5 | Ø15.5 | 5 |

| CS5[1.5]2.0A | 1.5(200) | 2.0 | 2.0(5) | 1800 | 2482 | 2659 | 3138 | 1400 | Ø400 | 11.5 | Ø15.5 | 5 |

| CS5[2.0]2.2A | 2(300) | 1.4 | 2(4) | 2000 | 2659 | 2706 | 3041 | 1500 | Ø400 | 9.5 | Ø17.5 | 5 |

| CS5[2.5]2.2A | 2.5(350) | 1.2 | 2.2(4) | 2200 | 2750 | 2683 | 3062 | 1500 | Ø400 | 11 | Ø17.5 | 5 |

| CS5[3]2.2A | 3(400) | 0.9 | 2.2(4) | 2300 | 3141 | 3134 | 3556 | 1650 | Ø400 | 11 | Ø15.5 | 5 |

| CS8[1]4A | 1(250) | 4 | 3.2(4) | 1880 | 2673 | 3210 | 3647 | 1000 | Ø520 | 9.5 | Ø21.5 | 8 |

| CS8[2]4A | 2(250) | 2.3 | 3.4(5) | 2112 | 3174 | 3614 | 4000 | 1510 | Ø560 | 12 | Ø21.5 | 8 |

| CS8[2.5]4A | 2.5(300) | 1.8 | 3.5(5) | 2460 | 3326 | 3740 | 4210 | 1866 | Ø560 | 13.5 | Ø21.5 | 8 |

| CS8[3]4.2A | 3(350) | 1.5 | 3.5(4) | 2200 | 3064 | 3609 | 4111 | 1800 | Ø520 | 11 | Ø21.5 | 8 |

| CS8[4]4.2A | 4(350) | 1.1 | 3.6(4) | 2500 | 3313 | 3414 | 3903 | 2050 | Ø520 | 11.5 | Ø21.5 | 8 |

| CS8[4.5]3.5A | 4.5(300) | 1.0 | 3.5(4), | 2400 | 3150 | 3500 | 3965 | 2050 | Ø520 | 11.5 | Ø21.5 | 8 |

| CS8[5]4.5A | 5(400) | 0.9 | 3.5(4) | 2520 | 3439 | 3571 | 4022 | 2200 | Ø520 | 12 | Ø21.5 | 10 |

| CS10[1]4A | 1(250) | 3.0 | 4(4) | 1880 | 2673 | 3210 | 3647 | 1000 | Ø520 | 10 | Ø21.5 | 10 |

| CS10[2]4A | 2(250) | 3.0 | 4(5) | 2112 | 3174 | 3614 | 4000 | 1510 | Ø560 | 12 | Ø21.5 | 10 |

| CS10[2.5]4A | 2.5(300) | 2.4 | 4(5) | 2460 | 3326 | 3740 | 4210 | 1866 | Ø560 | 13.5 | Ø21.5 | 10 |

| CS10[3]4.2A | 3(350) | 1.8 | 4.2(4) | 2200 | 3064 | 3609 | 4111 | 1800 | Ø520 | 11 | Ø21.5 | 10 |

| CS10[4]4.2A | 4(350) | 1.45 | 4.2(4) | 2500 | 3313 | 3414 | 3903 | 2050 | Ø520 | 11.5 | Ø21.5 | 10 |

| CS10[4.3]4.4A | 4.3(350) | 1.3 | 4.4(4) | 2500 | 3326 | 3442 | 3914 | 2200 | Ø520 | 11.5 | Ø21.5 | 10 |

| CS10[5]4.5A | 5(400) | 1.1 | 4.5(4) | 2520 | 3439 | 3571 | 4022 | 2200 | Ø520 | 12 | Ø21.5 | 10 |

| CS10[6]4A | 6(400) | 1.0 | 4.0(4) | 2900 | 3703 | 3805 | 4464 | 2150 | Ø520 | 13 | Ø21.5 | 10 |

| CS10[6.3]4.1A | 6.3(400) | 0.9 | 4.1(3) | 2800 | 3814 | 3760 | 4279 | 2200 | Ø520 | 11 | Ø21.5 | 10 |

| CS10[8.5]4.5A | 8.5(400) | 0.65 | 4.5(3) | 2960 | 3859 | 3870 | 4487 | 2590 | Ø520 | 11.5 | Ø21.5 | 10 |

| CS16[3]5.5A | 3(300) | 3.0 | 5.5(5) | 2390 | 3196 | 3681 | 4124 | 2000 | Ø560 | 13.5 | Ø28 | 16 |

| CS16[3.5]6A | 3.5(300) | 2.8 | 6(5) | 2500 | 3410 | 3737 | 4212 | 2100 | Ø560 | 14 | Ø28 | 16 |

| CS16[4]6A | 4(300) | 2.5 | 6(4) | 2543 | 3410 | 3737 | 4212 | 2220 | Ø560 | 12 | Ø28 | 16 |

| CS16[5]6A | 5(300) | 2 | 6(5) | 2660 | 3547 | 3827 | 4334 | 2200 | Ø560 | 14 | Ø28 | 16 |

| CS16[6]6A | 6(300) | 1.7 | 6(4) | 2893 | 3800 | 4016 | 4582 | 2430 | Ø560 | 13.5 | Ø28 | 16 |

| CS16[7]6A | 7(350) | 1.4 | 6(4) | 3200 | 3995 | 4087 | 4830 | 2300 | Ø560 | 14.5 | Ø28 | 16 |

| CS16[8]6.2A | 8(350) | 1.3 | 6.2(4) | 3200 | 3930 | 4067 | 4680 | 2672 | Ø560 | 13 | Ø28 | 16 |

| CS16[10]6A | 10(400) | 1 | 6(3) | 3000 | 4122 | 4176 | 4659 | 3000 | Ø560 | 12 | Ø28 | 16 |

| CS16[10]6.2A | 10(400) | 1 | 6.2(4) | 3000 | 4129 | 4057 | 4605 | 3000 | Ø560 | 14 | Ø28 | 16 |

| CS16[11]6.2A | 11(400) | 0.85 | 6.2(3) | 3200 | 3995 | 4138 | 4880 | 3000 | Ø650 | 12.5 | Ø28 | 16 |

| CS16[12]6.2A | 12(400) | 0.8 | 6.2(3) | 3300 | 4234 | 4209 | 4936 | 2968 | Ø560 | 13 | Ø28 | 16 |

| CS20[5]7 A | 5(300) | 2.6 | 7(5) | 2700 | 3605 | 4047 | 4588 | 2300 | Ø650 | 15.5 | Ø28 | 20 |

| CS20[6]7 A | 6(300) | 2.3 | 7(4) | 2850 | 3800 | 4397 | 4969 | 2450 | Ø650 | 14.5 | Ø28 | 20 |

| CS20[7]7 A | 4(350) | 1.6 | 7(4) | 2850 | 3913 | 4291 | 4798 | 2500 | Ø650 | 14.5 | Ø28 | 20 |

| CS20[8]7 A | 8(350) | 1.6 | 7(4) | 3000 | 3092 | 4290 | 4872 | 2580 | Ø650 | 14.5 | Ø28 | 20 |

Parameter 2:

| Specification | Volume (m3) | Material Density (t/m3) | Dead Weight (t) | Dimension (mm) | Chain Wheel Diameter (mm) | Operating Height (m) | Steel Rope Diameter (mm) | Lifting Height (t) | ||||

| A | B | C | D | E | ||||||||

| CS20[13.5]7.6 A | 13.5(400) | 0.9 | 7.6(3) | 3520 | 4499 | 4439 | 5115 | 3000 | Ø650 | 16 | Ø28 | 20 |

| CS25[6]8.3 A | 6(300) | 2.8 | 8.3(5) | 2800 | 3913 | 4404 | 4857 | 2400 | Ø720 | 15.5 | Ø32 | 25 |

| CS25[6.5]8.4 A | 6.5(300) | 2.6 | 8.4(4) | 2800 | 3913 | 4404 | 4857 | 2600 | Ø720 | 13.5 | Ø32 | 25 |

| CS25[6.5]8.5 A | 8.5(5) | 15.5 | ||||||||||

| CS25[7.5]8.4A | 7.3(300) | 2.2 | 8.4(4) | 2920 | 3995 | 4493 | 5109 | 2700 | Ø720 | 14 | Ø32 | 25 |

| CS25[9]9A | 10(350) | 1.8 | 9(4) | 3200 | 4304 | 4629 | 5200 | 2700 | Ø720 | 15 | Ø32 | 25 |

| CS25[10]8.9A | 10(350) | 1.6 | 8.9(3) | 3200 | 4304 | 4646 | 5207 | 2800 | Ø720 | 13 | Ø32 | 25 |

| CS25[10]9A | 9(4) | 15 | ||||||||||

| CS25[15]9.2A | 15(400) | 1.05 | 9.1(3) | 3720 | 4979 | 4896 | 5588 | 3200 | Ø720 | 14 | Ø32 | 25 |

| CS25[15]9.3A | 9.3(4) | 16.5 | ||||||||||

| CS25[17]9.4A | 17(400) | 0.9 | 9.4(3) | 3590 | 4969 | 4974 | 5668 | 3400 | Ø720 | 15 | Ø32 | 25 |

| CS25[17]9.6A | 9.6(4) | 17 | ||||||||||

| CS30[7]11A | 7(300) | 2.8 | 11(5) | 2800 | 3719 | 4585 | 4983 | 2800 | Ø800 | 15.5 | Ø38 | 30 |

| CS30[8]10.5A | 8(300) | 2.5 | 10.5(5) | 3100 | 4109 | 4913 | 5432 | 2700 | Ø800 | 16.5 | Ø36 | 30 |

| CS30[10]11A | 10(300) | 1.9 | 11(5) | 3550 | 4482 | 5035 | 5689 | 2700 | Ø800 | 17 | Ø36 | 30 |

| CS30[12]11.5A | 12(350) | 1.5 | 11.5(5) | 3649 | 4677 | 5124 | 5837 | 2800 | Ø800 | 19.5 | Ø36 | 30 |

| CS30[15]11.6A | 15(350) | 1.2 | 15(4) | 3780 | 4992 | 5369 | 6032 | 3150 | Ø800 | 17.5 | Ø36 | 30 |

| CS30[18]11.8A | 18(350) | 1 | 15(3) | 4000 | 5380 | 5437 | 6121 | 3050 | Ø800 | 15.5 | Ø36 | 30 |

| CS30[20]12 A | 20(450) | 0.9 | 12(3) | 4000 | 5380 | 5437 | 6121 | 3400 | Ø800 | 15.5 | Ø36 | 30 |

| CS30[26]12.5A | 26(450) | 0.68 | 12.5(3) | 4163 | 5457 | 5557 | 6292 | 3800 | Ø800 | 15.5 | Ø36 | 30 |

| CS35[9]12A | 9(300) | 2.5 | 12(5) | 3060 | 4280 | 5187 | 5587 | 2920 | Ø800 | 17.5 | Ø38 | 35 |

| CS35[15]13A | 15(350) | 1.5 | 13(4) | 3780 | 4992 | 5369 | 6032 | 3150 | Ø800 | 17.5 | Ø36 | 35 |

| CS35[22]13.5A | 22(400) | 0.9 | 14(4) | 4080 | 5223 | 5854 | 6682 | 3555 | Ø800 | 19.5 | Ø38 | 35 |

| CS40[9.2]14A | 9.2(300) | 2.8 | 14(4) | 3149 | 3913 | 4946 | 5414 | 3100 | Ø920 | 16.5 | Ø40 | 40 |

| CS40[12]14A | 12(300) | 2.2 | 14(4) | 3299 | 4677 | 5367 | 5824 | 3100 | Ø920 | 16.5 | Ø40 | 40 |

| CS40[22]14A | 22(300) | 1.1 | 16(4) | 4150 | 5554 | 5810 | 6564 | 3500 | Ø920 | 20 | Ø40 | 40 |

| CS40[26.5]16.5A | 26.5(400) | 0.9 | 16.5(4) | 4627 | 6239 | 6606 | 7447 | 4700 | Ø920 | 22 | Ø40 | 40 |

| CS52[10]19A | 10(300) | 3.0 | 19(5) | 3300 | 4695 | 5849 | 6326 | 2980 | Ø1020 | 20 | Ø46 | 52 |

| CS52[12.8]19A | 12.8(300) | 2.5 | 19(5) | 3500 | 4891 | 5865 | 6420 | 3200 | Ø1020 | 20.5 | Ø46 | 52 |

| CS52[14.5]19.2A | 14.2(300) | 2.2 | 19.2(5) | 3600 | 5086 | 5946 | 6602 | 3250 | Ø1020 | 21.5 | Ø46 | 52 |

| CS52[18]19.6A | 18(350) | 1.8 | 19.6(4) | 3800 | 5164 | 5986 | 6675 | 3500 | Ø1020 | 20.5 | Ø46 | 52 |

| 19.6(5) | 24 | |||||||||||

| CS52[21]20A | 21(350) | 1.5 | 20(4) | 4000 | 5359 | 6058 | 6808 | 3650 | Ø1020 | 21 | Ø46 | 52 |

| CS52[34.5]21A | 34.5(400) | 0.9 | 21(3) | 4600 | 6139 | 6435 | 7391 | 4300 | Ø1020 | 18.5 | Ø46 | 52 |

| CS63[16.5]23.4A | 16.5(300) | 2.4 | 23.4(5) | 4120 | 5752 | 6867 | 7537 | 3150 | Ø1120 | 23.5 | Ø52 | 63 |

| CS63[42]25.2A | 42(400) | 0.9 | 25.2(3) | 5069 | 6567 | 7316 | 8360 | 4500 | Ø1120 | 21 | Ø52 | 63 |

| CS70[16]26A | 16(350) | 2.75 | 26(4) | 3800 | 5478 | 6739 | 7262 | 3200 | Ø1120 | 19.5 | Ø52 | 70 |

| CS70[19]27A | 19(350) | 2.2 | 27(4) | 4120 | 5752 | 6852 | 7621 | 3400 | Ø1120 | 23.5 | Ø52 | 70 |

| CS70[46.5]28A | 46.5(350) | 0.9 | 28(3) | 5300 | 6852 | 7386 | 8387 | 4600 | Ø1120 | 21.5 | Ø52 | 70 |

| CS100[26]35A | 26(300) | 2.5 | 35(4) | 4670 | 6041 | 7076 | 8008 | 4100 | Ø1250 | 22.5 | Ø55 | 100 |

| CS100[40]36A | 40(350) | 1.6 | 36(3) | 5069 | 6567 | 7316 | 8360 | 4500 | Ø1250 | 21 | Ø55 | 100 |

| CS100[66]40A | 66(400) | 0.9 | 40(3) | 5800 | 7210 | 7570 | 8885 | 5100 | Ø1250 | 22.5 | Ø55 | 100 |

Related Products

-

- Motor Hydraulic Dual Scoop GrabElectro hydraulic grab with dual scoop can be fitted to the crane with one single rope. It is an efficient tool for load

-

- Mechanical Rectangle GrabWe are one of the largest manufacturers in the production of hydraulic, electro-hydraulic, and mechanical grabs in China